Product Details

|

|

|

|

||

|

||

|

Description

YWM-12N

The YWM -12N automatic road-Plate beveling machine is a new generation of Products.the use of high-quality transmission reducer works,efficient,energy-saving,environmentally friendly,easy to operate,easy to use a number of advantages:greatly reduce labor the amount of labor cost savings:while in line with the current Low-carbon.low energy consumption trends in environmental protection and philosophy.

The YWM -12N beveling machine speed of 1.5-2 meters per minute.less than 45 mm in thickness.tensile strength the road last 40kg/mm2 steel plate welding groove Processing a slope width of 12 mm.according to the actual fractional machining groove width of 18 mm.And can be arbitrarily adjusted within the range of 25°-45°bevel angle.

YWM-16N

YWM-16N series automatic moving type beveling machine,used in the groove prior to welding sheet metal Processing,the machine is mainly the use of rolling shear principle, to the work piece edge according to the required angle,groove volume cutting,in order to obtain the required welding groove。

YWM-16N automatic moving type plate groove machine is suitable for ordinary steel, cast iron、rigid plastic,non-ferrous metals and other materials ! before welding end surface chamfer groove tool,to solve the flame cutting.grinding pin operation process perspective is not standardized.slope rough、the working noise is big,Automatic materials according to the edges of the automatic walking,the machine has the advantages of convenient angle adjustment,convenient operation,per unit time,high efficiency,environmental protection has convenient operation,angle precision,surface roughness,fast speed,high efficiency. Optimization for carbon steel processing has the quite prominent characteristics.

YWM-16N type beveling machine to speeds beyond 1.5—2.5 meters per minute,45mm in thickness below the tensile strength steel plate for the 40kg/mm2 processed on an automatic road width of l6mm of the weld slope slope Mouth,according to the actual needs of the fractional width of 22mm can be processed to the slope。And 25°-45°range adjustable groove angle。

The models of machine groove covers nearly 80% customers in the actual need,Is a cost-effective comprehensive performance the best selling models。

YWM-2046

YWM-2046 road-style flat slope mouth machine,used in the groove prior to welding sheet metal processing,the machine is the use of milling principle according to the required angel on the Plate edge milling,to get the groove welding required.

YWM-2046 road-style flat slope mouth machine,To solve the flame cutting,grinding pin operation process of manual strength、angle of no specification,slope rough,the working noise is big, greatly reduce energy consumption,cost of oxygen acetylene gas. More effectively avoid the flame cutting plate deformation, rigidity degeneration.

YWM-2046 automatic moving type plate groove can automatically according to the edges of the automatic walking,the machine has the advantages of convenient angle adjustment, convenient operation,per unit time,high efficiency,environmental protection has convenient operation,angle precision,surface roughness,fast speed,high efficiency. Optimization for carbon steel processing has the quite prominent

BM-15

It is highly efficient machine for edge weld preparation and rounding off steel construction before painting or coating.

BM-15 beveling machine is portable muti-functional,apply to plate,square and irregualr beveling process, besides,it is used to pipes’s inner hole less than 50mm .

Advantage

Technical Parameters

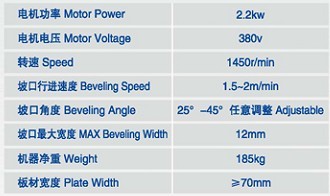

YWM-12N

The YWM -12N automatic road-Plate beveling machine is a new generation of Products.the use of high-quality transmission reducer works,efficient,energy-saving,environmentally friendly,easy to operate,easy to use a number of advantages:greatly reduce labor the amount of labor cost savings:while in line with the current Low-carbon.low energy consumption trends in environmental protection and philosophy.

The YWM -12N beveling machine speed of 1.5-2 meters per minute.less than 45 mm in thickness.tensile strength the road last 40kg/mm2 steel plate welding groove Processing a slope width of 12 mm.according to the actual fractional machining groove width of 18 mm.And can be arbitrarily adjusted within the range of 25°-45°bevel angle.

YWM-16N

YWM-16N series automatic moving type beveling machine,used in the groove prior to welding sheet metal Processing,the machine is mainly the use of rolling shear principle, to the work piece edge according to the required angle,groove volume cutting,in order to obtain the required welding groove。

YWM-16N automatic moving type plate groove machine is suitable for ordinary steel, cast iron、rigid plastic,non-ferrous metals and other materials ! before welding end surface chamfer groove tool,to solve the flame cutting.grinding pin operation process perspective is not standardized.slope rough、the working noise is big,Automatic materials according to the edges of the automatic walking,the machine has the advantages of convenient angle adjustment,convenient operation,per unit time,high efficiency,environmental protection has convenient operation,angle precision,surface roughness,fast speed,high efficiency. Optimization for carbon steel processing has the quite prominent characteristics.

YWM-16N type beveling machine to speeds beyond 1.5—2.5 meters per minute,45mm in thickness below the tensile strength steel plate for the 40kg/mm2 processed on an automatic road width of l6mm of the weld slope slope Mouth,according to the actual needs of the fractional width of 22mm can be processed to the slope。And 25°-45°range adjustable groove angle。

The models of machine groove covers nearly 80% customers in the actual need,Is a cost-effective comprehensive performance the best selling models。

YWM-2046

YWM-2046 road-style flat slope mouth machine,used in the groove prior to welding sheet metal processing,the machine is the use of milling principle according to the required angel on the Plate edge milling,to get the groove welding required.

YWM-2046 road-style flat slope mouth machine,To solve the flame cutting,grinding pin operation process of manual strength、angle of no specification,slope rough,the working noise is big, greatly reduce energy consumption,cost of oxygen acetylene gas. More effectively avoid the flame cutting plate deformation, rigidity degeneration.

YWM-2046 automatic moving type plate groove can automatically according to the edges of the automatic walking,the machine has the advantages of convenient angle adjustment, convenient operation,per unit time,high efficiency,environmental protection has convenient operation,angle precision,surface roughness,fast speed,high efficiency. Optimization for carbon steel processing has the quite prominent

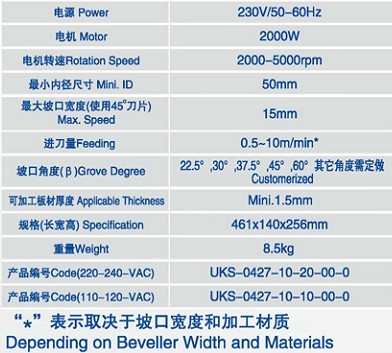

BM-15

It is highly efficient machine for edge weld preparation and rounding off steel construction before painting or coating.

BM-15 beveling machine is portable muti-functional,apply to plate,square and irregualr beveling process, besides,it is used to pipes’s inner hole less than 50mm .

Advantage

| YWM-12N YWM-16N | YWM - 2046 | BM-15 |

| Product Features:This machine adopts rolling shear mode groove High quality transmission reduce configuration,more efficient and stable; Damping walking fast groove; Adjustable bevel angle machining material thickness; Cold groove surface oxidation; For plate processing. |

Product Features:MiIIing BeveIing Dual-motor power,the professional electrical control, |

BM-15 Beveling Machine use on a variety of materials like steel, aluminum and stainless steel. Compact design and small overall dimensions make BM-15 an excellent tool in any working condition with high efficiency. One milling head enables beveling edges with radius of 3 or 4 or 5mm with use of 4 indexable R3, R4 or R5 inserts. Five milling heads enable beveling (other angles upon request). BM-15 is equipped with continuous bevel width adjustment, overheating protection and electronic speed control . |

Technical Parameters

| YWM-12N | YWM-16N |

|

|

| YWM - 2046型 | BM-15型 |

|

|

Copyright (c) 2006-2010 All Rights Reserved ShangHai Yowee

ICP:09001169

Address:Shanghai Fengxian District Wang Yang Industrial Park Yong Yang Road No. 189(201406)

ICP:09001169

Address:Shanghai Fengxian District Wang Yang Industrial Park Yong Yang Road No. 189(201406)